Floor Markings Make Your Factory Safer and more Efficient

Your factory floor sees a lot of traffic. Whether from employees or equipment, it supports the constant hustle and bustle of your business. The factory floor could also be a place for accidents and injuries to occur.

An effective way to prevent potential accidents and injuries is by clearly marking permanent aisles and passageways with floor marking tape, as required by the Occupational Safety and Health Association (OSHA). Floor marking is also a good way to improve efficiency.

More efficient operations

A standardized floor marking color system helps employees associate certain colors with certain areas or actions. This helps them quickly and easily move around the facility to complete their tasks and find what they need. A color-coded floor marking system helps to:

- Emphasize important information. Using floor tape to highlight your facility’s aisleways and exit paths clearly identifies the safest path through the facility. This helps keep pedestrians and forklifts safe and provides quick egress guidance in an emergency.

- Keep your facility organized by showing associations. For example, when you mark both a cart and the area the cart should be stored with the same color tape or paint, employees can easily associate when the cart is not in its intended location.

- Provide critical information at the point of need. When hazards are consistently marked with bright colors (red / yellow) it provides critical safety information to employees directly at the point of need where it is more pertinent.

- Provide critical information at the point of need. When hazards are consistently marked with bright colors (red / yellow) it provides critical safety information to employees directly at the point of need where it is more pertinent.

- Increase employee efficiency, because employees spend less time looking for what they need. For example, when trying to locate a certain material storage area, knowing what color floor marking to look for helps you find it faster.

Occupational Safety and Health Administration (OSHA) Floor Marking Guidelines

While several OSHA regulations dictate that permanent aisles and passageways must be clearly marked, there are no current government-mandated or even widely accepted industry standards that recommend what colors to use when marking floors.

However, when it comes to workplace visuals there are a number of relevant standards that require or imply the need for marking and color-coding:

Use of Mechanical Equipment §1910.176(a): Where mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made. Aisles and passageways shall be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard. Permanent aisles and passageways shall be appropriately marked.

General Environmental Controls §1910.144:

- §1910.144(a)(1) Red shall be the basic color for the identification of fire protection equipment and apparatus.

- §1910.144(a)(3) Yellow shall be the basic color for designating caution and marking physical hazards.

Means of Egress §1910.35: OSHA will deem an employer demonstrating compliance with the exit route provisions of NFPA 101, Life Safety Code, or the exit-route provisions of the International Fire Code (IFC), 2009 edition, to be in compliance with §1910.34, §1910.36 and §1910.37.

Letter of Interpretation §1910.22(b): The lines used to delineate aisles may be any color so long as they clearly define the area considered as aisle space. The lines may be composed of dots, square, strip or continuous. The recommended width of aisle markings varies from 2 in. to 6 in., therefore any width 2 in. or more is considered acceptable.

International Fire Code 2009:

- §1024.1 Approved luminous egress path markings delineating the exit path shall be provided...having occupied floors located more than 75 ft. above the lowest level of fire department vehicle access.

- §1024.2.1 A solid and continuous stripe shall be applied to the horizontal leading edge of each step and shall extend the full length of each step.

- §1024.2.4 Perimeter and floor mounted demarcation lines shall be placed within 4 in. of the wall and extend to within 2 in. of the markings on the leading edge of landings. Demarcation lines shall be 1 in. to 2 in. wide with interruptions not exceeding 4 in.

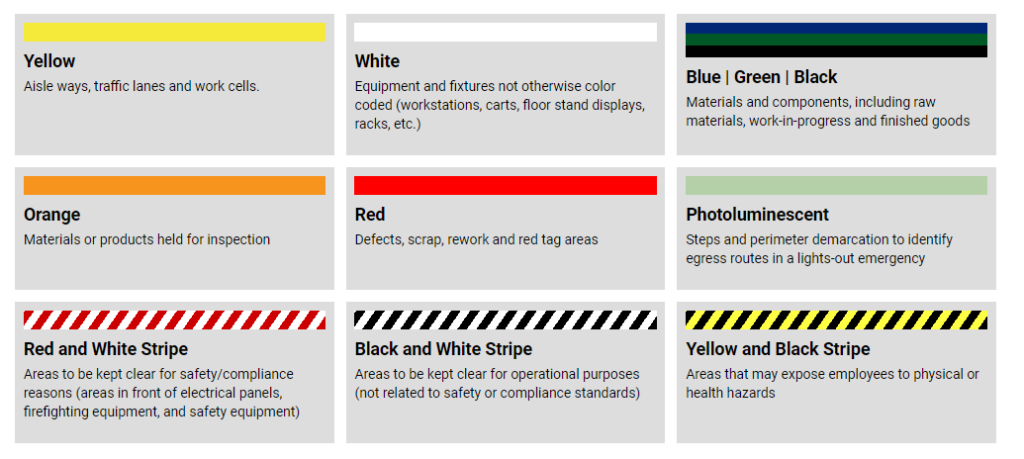

Floor marking color standards guide

With the right colors in the right places, you can easily keep workers on the right path and identify equipment, storage areas, hazardous areas, forklift traffic and more. Use as few colors as possible to make it easier for employees to remember the meaning of each color and reduce the number of floor marking products you need.

Product Suggestions:

UltraTape has several floor marking products created especially for cleanroom environments: