Technical Tape and Label Information

UltraClean:

- Offers the highest level of cleanliness available for today's critical environments.

- Suitable for use in Class 100 to Class 1 cleanrooms.

- UltraTape's web cleaning system dissipates the static layer, allowing both sides of the label stock to be cleaned.

Classic Clean:

- Offers cleanroom packaging and is ideal for keeping products safe from environmental contamination prior to use.

- Suitable for Class 10,000 (ISO Class 7) to Class 100,000 (ISO Class 8) cleanrooms.

- No visual material transfer on Glass

- Over 24 hour at room temperature

- Acrylic (low and medium tack)

- Lowest residue over long period of time (years)

- Synthetic Rubber

- Low residue over shorter time (month)

- Natural Rubber

- Highest residue over long time

- Proprietary Manufacturing process

- Cleanroom Certified

- Particle counts (bag and pull counts)

- Standard Tape ( avg. ›100K 0.3 um )

- UltraTape CR (range ‹1 to 100 0.3 um)

- Double bagged and sealed in a Cleanroom to assure Cleanroom delivery

- Application surface

- Temperature

- Permanent vs. removable (time applied)

- Chemically resistant

- Cleanliness – particle free

- Residue Free

- Anti-Static or Conductive

- Color

- Circuit Board Masking

- Cleanroom

- Box sealing

- Plastic tenting

- Pipe wrap

- Floor marking

- ESD Tape

- Medical / pharmaceutical

- Autoclavable

- Surface Protection

- Sterilization indicator

- High Temp

Glossary Of Technical Terms:

Adhesion: (Peel Adhesion) How well the tape sticks to a surface. Usually measured in ounces of pull (force) required to remove a one-inch wide strip of tape from a steel plate (i.e., adhesion to steel). Usually measured in ounces/inches. The same tape usually adheres differently to different surfaces.

Adhesion to Backing: The force necessary to peel the tape from its own backing (i.e. to unwind the tape).

Adhesive: The most common type of adhesive is a blend of rubber and resins. Other pressure sensitive adhesives are acrylics and silicone. Acrylics are highly solvent and weather-resistant while silicones have a high resistance to heat.

Backing: The material on which the adhesive is carried (i.e., paper, cloth, film, vinyl, etc.).

Carrier: Sometimes used to refer to the backing material, particularly in double-faced pressure-sensitive tapes.

Classic Clean: Ideal for keeping products safe from excess environmental contamination. Suitable for Class 100,000 to Class 1,000 cleanrooms.

Conformability: The ability to be applied to irregular surfaces. This property is related to the elongation (stretch) of the backing.

Creeping: The ability of certain plastic tapes to shrink back to their original length after being stretched (i.e., vinyl). Also called elastic memory.

Elongation: (Ultimate) The percentage of stretch at the breaking point of the tape.

Liner: The material used between tape layers to prevent adhesion of the tape to itself—usually used for double-coated tapes.

Quick-Stick: The adhesive adheres immediately to the surface when applied. Rubber adhesive have good quick-stick properties.

Pressure-Sensitive Adhesive: A sticky substance which adheres by application of pressure alone, and does not require the use of water, heat, or solvents.

Release Coating: A thin layer of a waxy substance, which reduces the adhesion to backing (i.e. reduces the unwind strength).

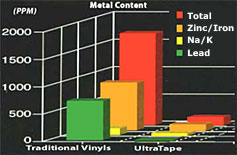

Residues: Adhesive transferred from the tape to the surface applied. Heat, moisture, sunlight, reactions to the surface, creeping, tape age, and many other factors influence the potential to residue.

Tack: The property of the adhesive, which is defined by the stickiness (i.e., high-tack, medium-tack, low-tack).

Telescoping: Deformation of the roll due to the winding force exceeding the adhesion to backing. The tape roll begins looking like a “telescope”. Smaller widths telescope more than larger widths. Heat accelerates.

Tensile Strength: Force needed to break the tape, frequently expressed as oz/inch.

UltraClean: Denotes UltraTape exclusive UltraClean Certification. Suitable for Class 100 to Class 1 cleanrooms. UltraTape's web cleaning system dissipates the static layer, allowing both sides of the label stock to be cleaned.